Coatings, Inks, and Treatments for Industry-Leading Innovation

Partner with CPS for Precision, Performance, and Custom Solutions that Elevate Your Products and Exceed Expectations

Transform your coatings and inks with precision particle surface modifications that solve formulation challenges to deliver enhanced color consistency, improved dispersion, and optimized performance properties.

Particle-Level Innovation for Coating, Ink, and Surface Treatment Excellence

At Custom Processing Services, we specialize in particle-level precision that drives breakthrough improvements in your formulations. Our advanced surface treatment capabilities, combined with our strong client partnerships, can help you overcome common challenges and unlock new possibilities for your products.

Our expertise: Surface modification, particle coating, and conditioning technologies that enhance color, finish, durability, application, and eco-friendly performance characteristics.

Whether you're looking to improve surface durability, develop new protective barriers, or innovate within your industry, our expert team is ready to bring your vision to life.

Common Formulation Challenges We Solve

Poor pigment

dispersion

Inadequate surface treatment creates clumping, color inconsistency, and reduced performance in final applications

Wettability

issues

Particles that resist proper dispersion in water-based or solvent-based systems compromise product quality and application properties

Agglomeration

problems

Particle clustering during storage or application affects color uniformity and surface finish quality

Handling

difficulties

Dusting, poor flowability, and processing challenges that slow production and increase waste

Our solution: Advanced particle surface treatments that modify surface chemistry, improve dispersion, and optimize particle behavior in your specific formulations

Optimizing Particles for Breakthrough Inks & Coatings

Particle Surface Modification

- Convert hydrophobic particles to hydrophilic for improved water-based formulations

- Apply nano-coatings to optimize particle behavior and performance

- Modify surface chemistry to prevent unwanted interactions between ingredients

Surface Conditioning & Shaping

- Spheronization for uniform particle surfaces and improved flow properties

- Surface smoothing to enhance gloss and color tone in pigments

- Controlled roughening for specific adhesion characteristics

Particle Coating Technologies

- Encapsulation that completely replaces original surface properties

- Protective coatings to prevent degradation or unwanted reactions

- Functional coatings that impart new capabilities to existing particles

Specialized Treatments for Coatings & Inks

- Surfactant treatments to alter pigment hue and brightness

- Oil treatments to prevent dusting in micronized materials

- Silanization for better filler integration and reinforcement

Applications & Industries We Serve

Architectural Coatings

- Improved pigment dispersion for consistent color and coverage

- Enhanced durability through particle surface optimization

- Better flow and leveling properties for superior finish quality

Industrial Coatings

- Optimized filler performance for strength and thermal stability

- Enhanced corrosion resistance through surface-treated additives

- Improved adhesion characteristics for challenging substrates

Printing Inks

- Superior color vibrancy through optimized pigment surface treatments

- Enhanced flow properties for consistent print quality

- Improved stability and shelf life performance

Specialty Formulations

- Custom surface treatments for unique performance requirements

- Eco-friendly modifications for sustainable formulations

- Advanced functional coatings for specialized applications

Our Technical Approach

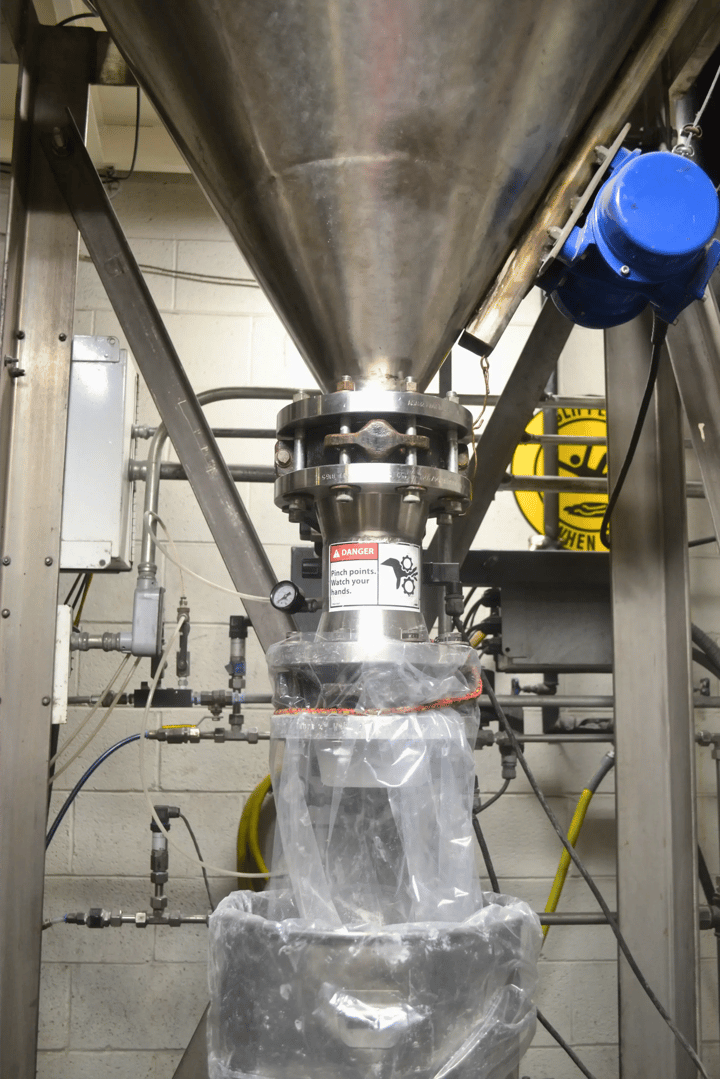

- Fluid bed systems for precise particle coating and treatment

- Air jet mills for surface modification and particle shaping

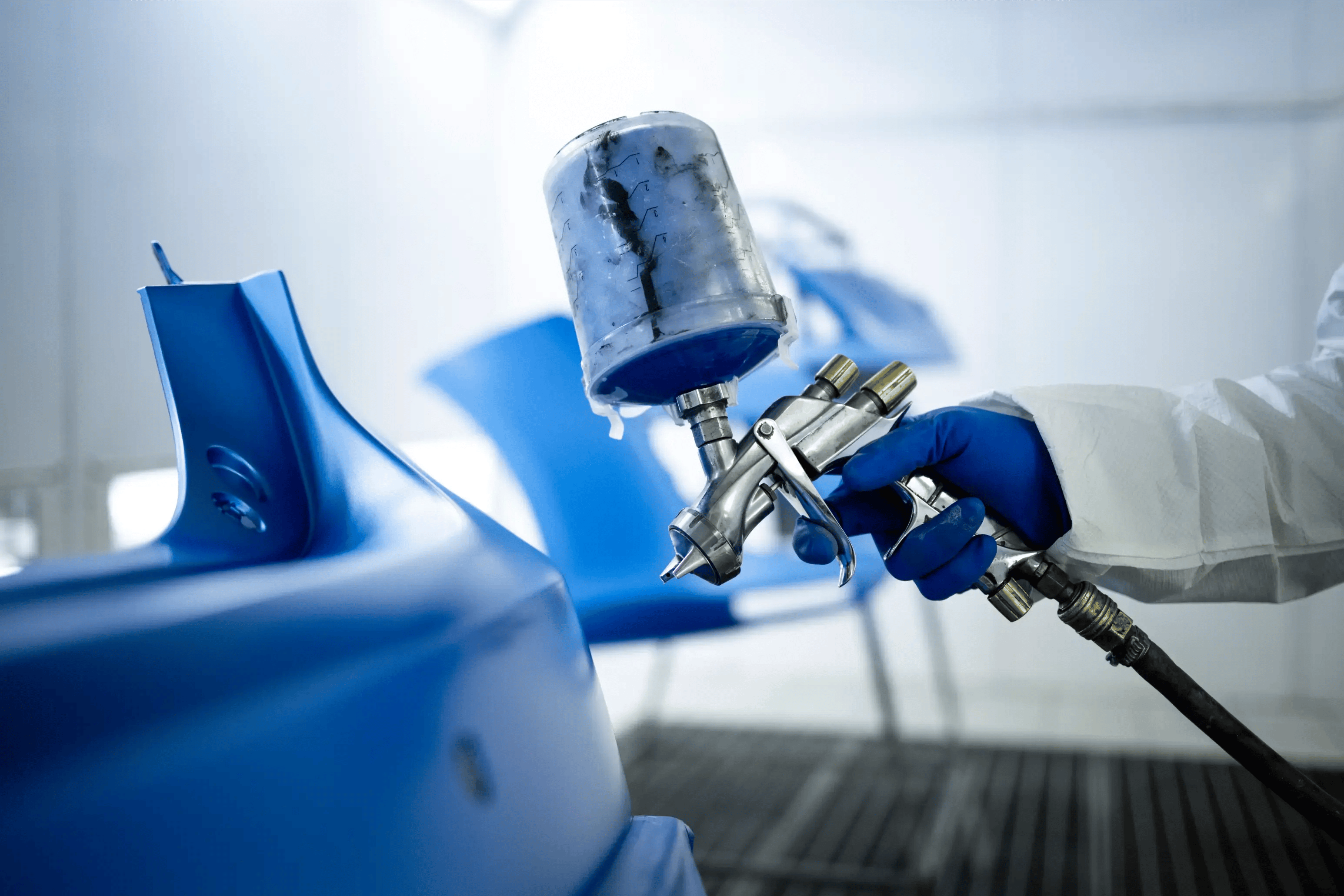

- Specialized spray systems for controlled coating application

- Prilling and melt spraying equipment for particle reshaping

- Material analysis to understand current limitations

- Custom treatment development for your specific requirements

- Pilot testing to optimize treatment parameters

- Scale-up support for production implementation

- Comprehensive particle characterization and analysis

- Surface property verification and performance testing

- Consistent treatment application across production batches

- Complete documentation for regulatory compliance

Your Complete Formulation Development Partner

With decades of industry experience, we combine advanced processing capabilities with a deep understanding of materials and application methods to support every phase of your formulation journey. From heat treating and batching to custom coating solutions, we’re equipped to help you push the boundaries of what's possible while consistently exceeding expectations.

If you’re searching for a partner that truly understands your industry and can deliver results that make a difference, let’s collaborate and create something exceptional together.

Explore custom toll processing solutions

Tailored to your materials, industry, and production goals

.png?width=100&height=110&name=CPS-Logo-rgb-no-callout%20(1).png)