Capabilities, expertise, and processes for superior drying.

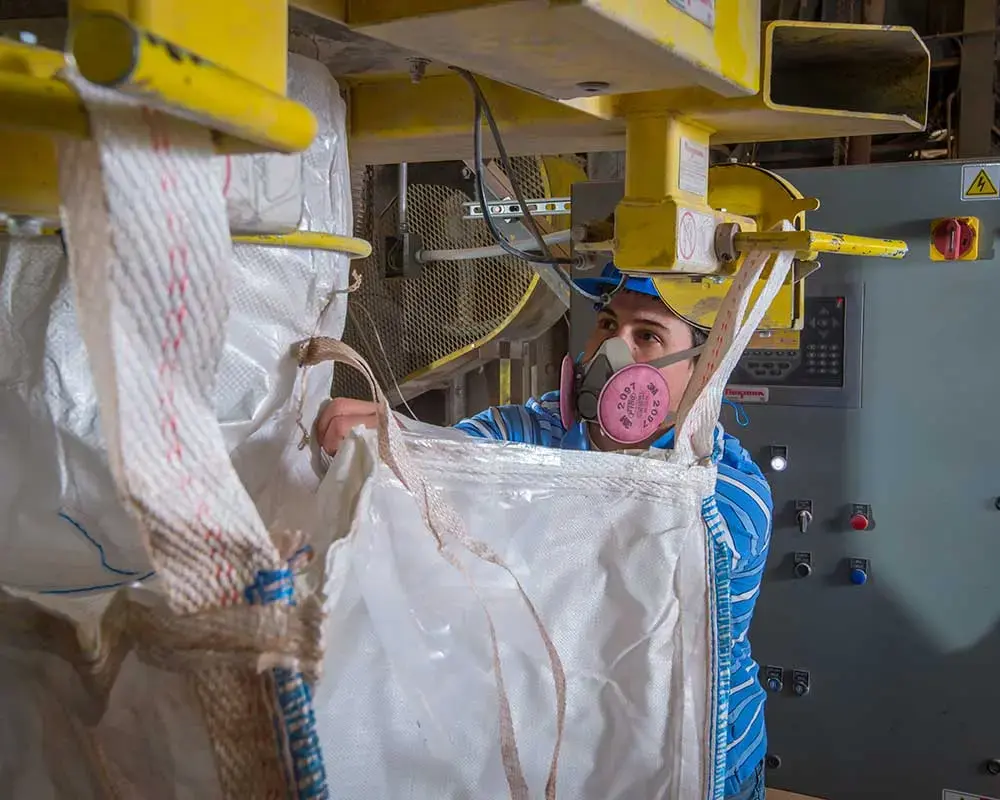

Your need is unique – so our team works to examine the material, quantity required, and particle shape and size to select the best toll drying method to meet your required moisture specification. Our contract drying services rely on our various industrial drying equipment, from flash drying’s hot gas jet stream to thermal heat transfer to a fluidized bed.

Our flash drying process uses a hot gas jet stream to provide moisture reduction, deagglomeration, and minor size reduction to specification within a 14-inch, large-volume flash dryer. The flash dryer uses recirculating loop flash drying — low-pressure jets of hot air — to break down materials, producing dry, discrete particles from powders, filter and centrifuge cakes, or slurry feed. Our process allows heat-sensitive materials to be dried without degradation.

An additional 6-inch flash dryer handles 3- to 4-truckload quantities. We specialize in the precision drying of organic and inorganic materials, minerals, and chemicals.

Learn More:

Mainly used to dry particles larger than 50 microns, the fluidized bed drying process subjects solid particles to conditions that cause them to behave like a fluid. When air flows through a perforated distributor plate, it supports the particles and dries them. Our equipment has a fully adjustable, large drying temperature range that is “gentle” enough to maintain product particle size and shape. Batching allows for various time, temperature, and moisture contents.

Learn More: