Nanomilling: Where Small Particles Make a Big Impact

Nanonization (sometimes also called nanoization) refers to the processes used to make nanoparticles that range in size from 1 nanometer (nm) to 100 nm. Numerous biological processes occur at this nanoscale level. In the human body, hemoglobin measures about 5.5 nm in diameter. DNA is even smaller — one strand measures just 2 nm in diameter.

Materials can behave very differently at this scale due to the vastly changed volume-to-surface area ratio of particles. This is why nanomilling technologies are playing an increasing role in manufacturing advancements across all industries.

Let’s take a closer look at nanomilling technologies, examining their advantages and disadvantages, and explore how a toll processor can assist in achieving this challenging particle size range.

WHAT ARE NANOPARTICLES?

Nanoparticles can be fabricated using bottom-up or top-down methods. Bottom-up nanofabrication involves constructing particles using chemical processes, whereas top-down nanofabrication refers to grinding or milling techniques used to reduce the size of larger particles. While bottom-up synthesis and form-in-place processes generate high-quality nanoparticles, they’re expensive and they require highly specialized, dedicated equipment.

Grinding, on the other hand, uses the same types of equipment as micronization — but with technical experts manipulating and adjusting their operations to achieve the target particle size range.

There is no one type of nano grinding mill, and not all milling methods or equipment can achieve nanoparticles. Techniques such as nanomilling, ball mills, dry and wet media mills, and jet mills can all be used to reduce particles down to the nano range.

SMALL BUT POWERFUL, NANOPARTICLES ARE IN HIGH DEMAND

Nanoparticles find broad applications across several industries including healthcare, cosmetics, pharmaceuticals, agriculture, optical technology, battery production, ceramics, pigments, and industrial minerals.

Nanonization processes vastly increase the available surface area per particle of material. These changes determine how the material behaves, as well as how easily it can interact with other materials, with living systems, and various environments. Benefits of achieving these ultrafine particle sizes include:

- Increased uniformity (not only in size, but also in particle shape and mass)

- Decreased dispersity or dissimilarity of size (measured in Đ or PDI, polydispersity index)

- Improved dissolution of compounds that are not highly soluble in water

- Enhanced reactivity and bioavailability

The changes in material properties can enhance the effectiveness of a formulation. This allows manufacturers to use significantly less of a high-value ingredient or an ingredient that might otherwise cause considerable side effects or environmental impact.

These enhancements add up to improved sustainability and cost controls, more effective and better tolerated medications, brighter paints and inks, and even stronger industrial materials.

WET MILLING: THE RELIABLE NANO GRINDING APPROACH

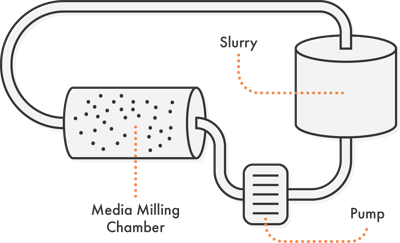

Wet grinding presents a straightforward approach to attaining nano-scale particle sizes. In this process, inert, nontoxic milling media such as resin, glass, or stabilized zirconium oxide is added to the raw material and carrier liquid for milling. In the wet mill, the material is added to a liquid, often with surfactants or dispersants added, and recirculated through the grinding chamber until the target particle size range is achieved.

As particles circulate through the media, the wet mill’s action fractures them into nanoparticles, further reducing their size even from their already small state. In general, the smaller the milling media size, the smaller the final particle size. Wet media milling produces very good outcomes in terms of both particle fineness and tight size distributions.

Milling media are selected based on their ability to grind materials effectively without undergoing significant wear themselves. This is crucial in preventing contamination of the final milled particles post-milling and subsequent separation from the media.

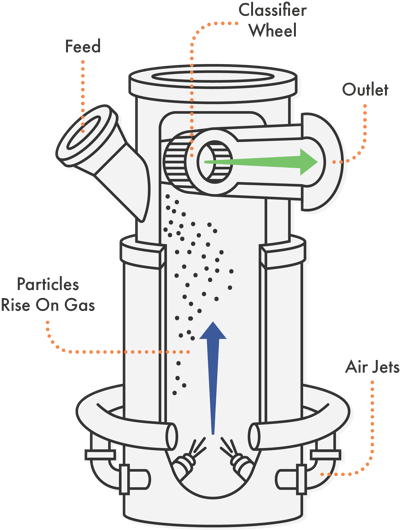

FLUIDIZED BED JET MILLING FOR NANOPARTICLES

One drawback of wet milling is its inherent wetness. For materials needed in a dry state, a drying step is required after wet milling. Drying, in turn, is followed by a deagglomeration step, since ultrafine particles often tend to clump together when dry. In addition, the dispersing agents often used in wet milling can be unwanted in the end product.

Fortunately, industry demand for very fine, dry powder materials is driving innovations in dry milling methods. Fluidized bed jet mills jet mills are ideal for nano grinding since fluidization prevents dry materials from forming agglomerates.

Jet milling with superheated steam allows for the production of nanoparticles and simultaneously dries the feed material. Steam can be introduced into the grinding chamber at higher pressure than air, achieving higher jet velocities and increasing the energy inside the milling chamber. The fluidized bed jet mill’s integrated internal classifier ensures a tight particle size range.

While this technique may not be ideal for heat-sensitive materials, fluidized bed jet mills utilizing superheated steam can produce nanoparticles from various minerals and pigments.

NAVIGATING THE PROS AND CONS OF WET AND DRY MILLING METHODS

Wet and dry milling methods have their advantages and disadvantages. Nanoparticles often agglomerate, posing challenges for dispersion after grinding. Wet milling tackles this issue by encapsulating each nanoparticle within the liquid slurry.

On the other hand, wet milling presents the possibility of introducing dispersant and surfactant additives into the final product. Dry methods like jet milling can achieve the desired particle size without using milling media.

In comparison to wet milling, jet milling processes typically demand more energy. However, opting for wet milling for a final product in a dry powder form entails selecting an energy-intensive drying process subsequent to the milling stage. Dry milling techniques, including fluidized jet milling with superheated steam, can save this step.

The bottom line is this: Talk to an expert about which method is most suitable for your material and most cost-effective for your project.

It’s evident that not every milling technique is compatible with all materials. This underscores the importance of experience and scientific expertise.

Ultimately, relying on a trusted toll processor’s team of material scientists, R&D experts, and technical professionals can assist in evaluating the pros and cons of various nanomilling methods, enabling you to select the most suitable process for your objectives.

The continuous evolution of milling methods and technological improvements is expanding the realm of nanonization across various materials and industries like never before. With guidance from the appropriate toll processing team, attaining nanoparticles for your products is within reach.

Get started planning your next milling project with our free Grinding Project Checklist. Click below to download your copy now.

.png?width=100&height=110&name=CPS-Logo-rgb-no-callout%20(1).png)